3 Costly Mistakes to Avoid in Shoring Design (And Why a Shoring Engineer is Crucial)

For any general contractor or developer, a construction project’s success is measured by three things: safety, budget, and timeline. A poorly executed shoring plan can jeopardize all three. While it may seem like a temporary part of the job, shoring is a critical structural element, and cutting corners can lead to catastrophic failures and devastating financial consequences.

As a licensed Shoring Engineer firm, we’ve seen the difference professional design makes. This guide will cover the three most common—and costly—mistakes we see on job sites and explain why a qualified engineer is not a line-item expense, but an essential investment.

Table of Contents

What is the Role of a Shoring Engineer?

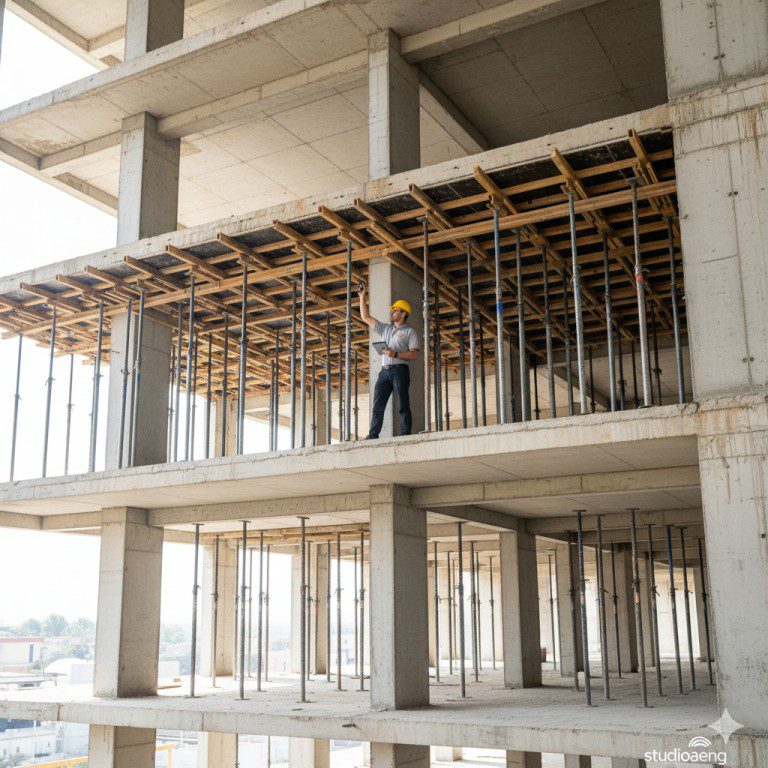

A Shoring Engineer is a specialized type of Structural Engineer who designs the temporary support systems used during construction. This includes designing supports for deep excavations, concrete formwork for multi-story buildings, and scaffolding for heavy loads. Their job is to ensure that the site remains stable and safe for workers throughout the entire construction process.

The 3 Most Costly Shoring Mistakes

1. Underestimating Soil and Lateral Pressures

This is a frequent and dangerous error, especially in Florida’s sandy and often water-saturated soil. A generic shoring plan that doesn’t account for the specific soil type, water table, and adjacent structures is a recipe for disaster. A professional Shoring Engineer will analyze the geotechnical report for your site and design a system (like soldier piles, lagging, or sheet piles) that can safely withstand the immense lateral pressures of the surrounding earth. Failure to do so can lead to trench collapse, a leading cause of construction site fatalities.

2. Using Inadequate or Improperly Installed Formwork Shoring

For multi-story concrete buildings, the formwork shoring must support the immense weight of wet concrete. We often see mistakes like using undersized shoring posts, incorrect spacing, or inadequate bracing. A formwork collapse not only destroys materials and causes massive delays but also poses a severe risk to workers. A qualified engineer’s plan will specify the exact type, size, and layout of the shoring system required to carry the load safely. This is a critical area for professional Shoring Inspections.

3. Lack of Proper Reshoring Plans

After a concrete slab is poured, it needs time to cure and gain strength. The shoring cannot be removed all at once. Reshoring is the process of partially removing and relocating shores to support the new slab while it cures, allowing construction to continue on the floors above. A professional Shoring Engineer will provide a detailed reshoring sequence and schedule. Removing shores too early or in the wrong order can overload a “green” slab, causing it to crack or even collapse. You can learn more about our comprehensive approach on our Shoring Design Specialist page.

The Engineer’s Role in Safety and Compliance

Beyond preventing collapse, a professionally designed shoring plan is a key part of your legal and regulatory compliance. It ensures your project adheres to the strict safety standards set by the Occupational Safety and Health Administration (OSHA). Having a sealed engineering plan on file is your best defense against liability and demonstrates a professional commitment to site safety.

Invest in an Expert Shoring Engineer Upfront

The cost of hiring an experienced Shoring Engineer is a tiny fraction of the potential cost of a shoring failure in terms of project delays, legal fees, and, most importantly, human life.

Contact us today to discuss your project’s requirements and let our team provide the expert shoring design and Shoring Inspections you need to build with confidence.